Fuel Cell Technologies

Quality Control for Fuel Cell Production

Quality Control for Fuel Cell Manufacturers

Quality control (QC) for fuel cell manufacturing is crucial for achieving sustainable transportation options that are affordable, durable, and safe. Additionally, making immediate PEM quality control decisions allows manufacturers to improve efficiency and maximize quality. Therefore, reliable, real-time QC for fuel cell production is essential in scaling up operations and driving cost reductions in manufacturing processes, thus enabling widespread accessibility to clean transport and reducing the impacts of global climate change.

PEM Quality Control From Lab to Plant Floor

With the increased demand for fuel cell and battery-powered electric vehicles, profiling the substrate or loading is crucial in manufacturing. NEX LS, an in-line linear scanner for web applications, provides real-time results throughout these processes and is an invaluable tool for roll-to-roll manufacturing and new product development. It offers real-time quality control of platinum, iridium, or other loadings used in PEM fuel cell production.

- Cross and down machine profiling

- User-defined measurement patterns

- Continuous monitoring for quick defect detection

Video

Additional Notes

- NEX LS Overview

- The EDXRF Method

Reliable Fuel Cell Loading QC

Whether monitoring Pt, Ir, or exploring other fuel cell loadings, NEX LS helps ensure quality and uniformity. To satisfy the evolving needs of the market, it offers continuous on-line inspection of these without the need to stop production for at-line checks. NEX LS helps technicians make real-time decisions and achieve reliable fuel cell loading quality control.

- Cross and machine direction profiling

- Easy self-installation

- Configurable to meet your process control needs

- Easy automatic calibration and operation

- Minimal routine maintenance and 2-year warranty

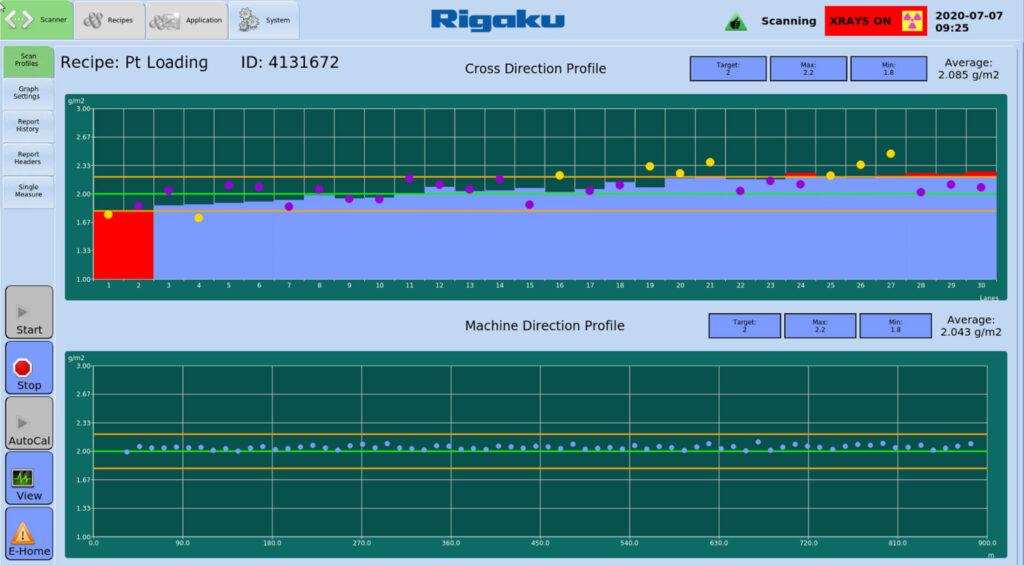

Furthermore, NEX LS is a compact in-line system that is easily installed and customized to meet process control needs for roll-to-roll (R2R) applications. Its analytical head sweeps back and forth across a moving web, and real-time data displays as a graphical cross direction and machine direction profile. Users can choose full scanning mode or user-defined fixed analysis positions.

The NEX LS software is easy to use and provides a clear visual representation of the process, helping users make immediate PEM loading quality control decisions. The real-time results help technicians address any questions or concerns related to the quality of the entire roll.

Roll Reporting for Fuel Cell QC

Scaling up production of today’s fuel cell technologies from lab to plant can have significant challenges. However, to help overcome these, advanced roll reporting can lead to a better understanding of critical defects and thresholds for quality.

In addition to real-time process control for fuel cell production, NEX LS offers roll reporting capabilities for quality records or audit trails. Recordings include machine direction, cross direction, and full lane average graphs. Users can customize reports, export them as PDF or CSV, and store copies to USB or a network using industry-standard communications protocols.

Proven EDXRF Technology for Fuel Cell Production QC

NEX LS features proven Rigaku EDXRF technology. EDXRF (energy dispersive X-ray fluorescence) is a non-destructive technique and offers users valuable information about the material or products as they are being produced. NEX LS serves web applications by performing real-time coat weight analysis.

The measuring head, mounted on a rigid beam, is equipped with a linear traversing mechanism ensuring constant head-to-surface distance. Where needed, the elemental composition of a coating is measured directly. In contrast, coat weight (or coating thickness) may be measured directly (where the counting rate for an element is proportional to thickness) or indirectly by measuring attenuation of some substrate element (where the counting rate is negatively correlated to thickness).

How Does This Technology Work?

When the analytical head sweeps back and forth across a moving web, source X-rays enter the product, exciting atoms in the material. The elements in the coating excite and fluoresce characteristic X-rays back to the detector. Users can choose full scanning mode or fixed analysis positions. The scanner transmits these measurements to a console box and industrial touchscreen computer, and real-time data displays as a graphical cross-direction and machine-direction profile.